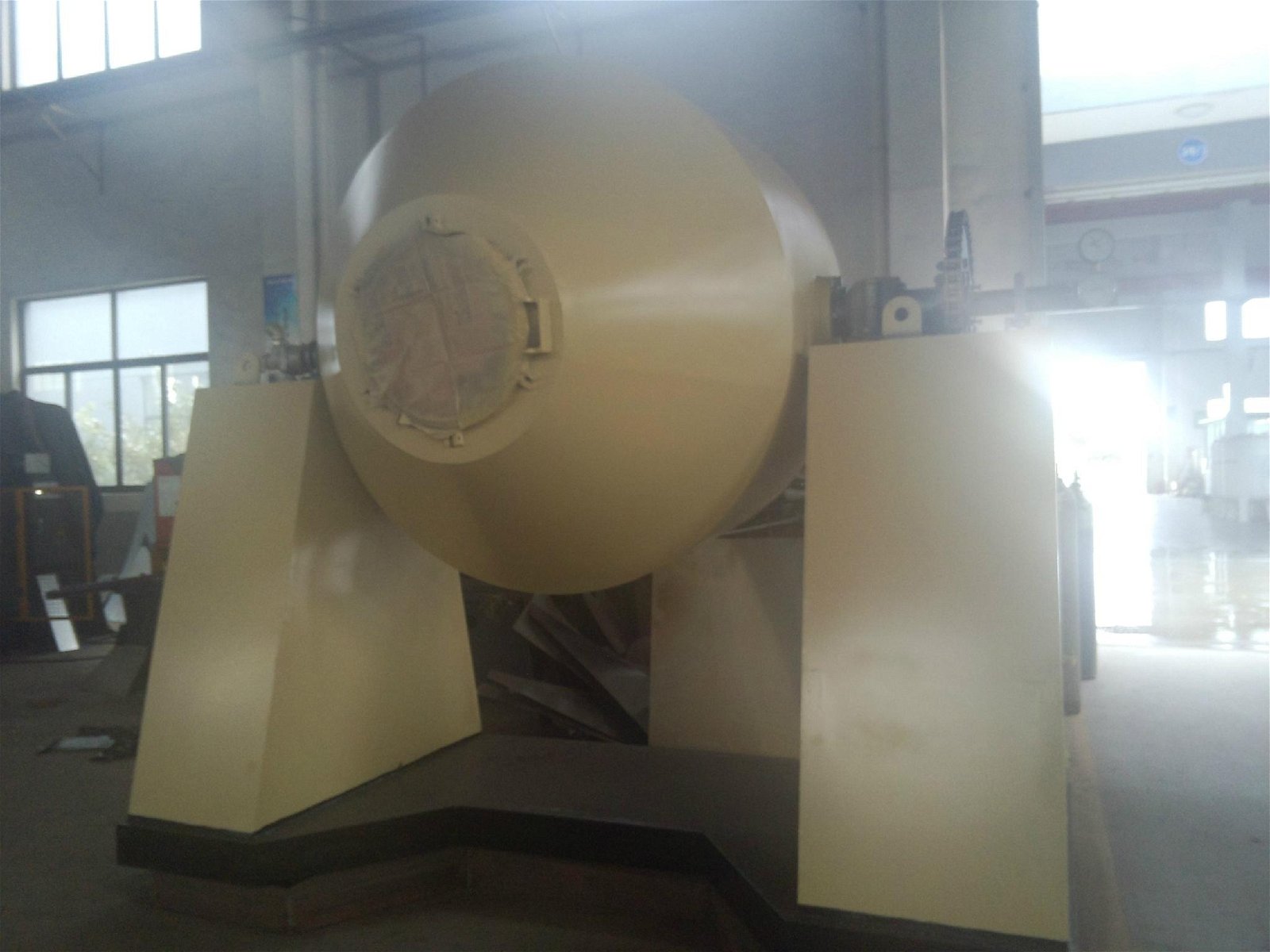

Glass-lined Double Cone Rotary Vacuum dryer

Model No.︰300L 到5000L

Brand Name︰BAOTANG

Country of Origin︰China

Unit Price︰-

Minimum Order︰1 pc

Product Description

GLASS-LINED DOUBLE CONE ROTARY VACUUM DRYER

1、working principle

This dryer under the vacuum condition, carries on the heating in the jacket by the steam or the hot water, is directly through the hot energy in the shell inside and the wet materials contact, depends on the tube body rotation, tumbles unceasingly the material. After the material heat absorption evaporates the steam, extracts outside continuously the tube through the vacuum pump after the steam exhaust pipe, thus speeds up the material the drying velocity, tumbles unceasingly along with the material, achieves the material even dry goal. This equipment and the heating area same general drying box and the kang type heater compares, the dry thermal efficiency may become time of enhancement, and can improve the work condition and the labor intensity.

2、Use of GL RCVD

This factory production dryer is one kind of multipurpose machine, is suitable in powdery or granular material vacuum drying and the mix, also is suitable specially in has the following request material.

1). Cannot accept the high temperature;

2). Easy to oxidize;

3). Has the strict request to the crystallization shape;

4). Has the strict limit to the metallic ion content;

5). Requests the remaining volatile matter content to be extremely low;

6). Dry when discharges the steam must recycle.

The material the dry merit may evaporate under the vacuum for the volatile matter under the low temperature, may be suitable hotly sensitive, the hatred oxygen class material is dry, in the shell of tank the glass lining, has smoothly, clean does not cake characteristic of the material

Uses this aircraft to be possible to arrange several operation sequences in a machine completes successively. Therefore can save the equipment, reduces the operating time, saves the energy, reduces the labor intensity, reduces the leak and the impurity mix opportunity, thus may obtain the high-purity product.

3、Performance&Specification

1)Design pressure:

Vessel inside:-0.1Mpa(vacuum) Jacket<0.1Mpa

2)Max.working pressure:

Vessel inside: -0.1Mpa(vacuum) jacket<0.1Mpa

3)Medium: Organic powder material (PH<12)in the shell, water or vapor in the jacket.

4) Maximum temperature: 140℃ (for example when user request oil heating may be bigger than with design relation temperature 140℃)

5)Shell of tank rotational speed: 4~8 revolution of/minutes (when user request may match velocity modulation electrical machinery)

Payment Terms︰ T/T,L/C

Product Image